Business Area

HOME

Business Area

Machine Vision

AI Inspection Solution (MOAI)

AI Inspection Solution (MOAI)

AI Inspection Solution (MOAI)

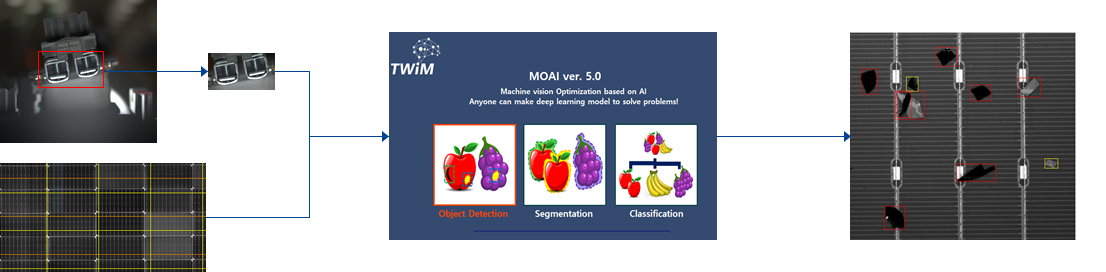

AI Inspection Software detects the defects accurately and quickly inspected to dramatically reduce defect rates.

Isn't it really hard to visually inspect each product at the manufacturing site?

However, it is not possible to introduce unproven AI testing software in the field.

With MOAI, TWIM's AI inspection software with successful deployment experience in a wide range of industries, product defects can be accurately and quickly inspected to dramatically reduce defect rates. Also, TWIM's MOAI customize for each process, so the process adaptability is the best.

Now, with MOAI, increase production quality and increase your brand credibility.

However, it is not possible to introduce unproven AI testing software in the field.

With MOAI, TWIM's AI inspection software with successful deployment experience in a wide range of industries, product defects can be accurately and quickly inspected to dramatically reduce defect rates. Also, TWIM's MOAI customize for each process, so the process adaptability is the best.

Now, with MOAI, increase production quality and increase your brand credibility.

Hybrid vision inspection with rule-based pre/post-processing MOAI Plus(Hybrid AI Vision Inspection with Rule-based Pre/Post-Processing)

Overview

MOAI Plus is hybrid AI vision inspection software that integrates pre/post-processing of inspection images to improve defect inspection efficiency or overcome inspection difficulties with just MOAI.

Features

- Hybrid inspection based on rules and deep learning for defect classification, defect location, and area detection

- Fast defect inspection using a small neural network by minimizing the area of interest in the captured images (Pre-Processing)

- Changes defect criteria and adjusting product yield by setting parameters for defect shape and size (Post-Processing)

- Parallel defect inspection by dividing high-resolution, large-capacity images into sizes suitable for learning and inspection (Image Partitioning)

- Defect inspection with only good image learning, CCTV video analysis, and anomaly detection in manufacturing equipment (Anomaly Detection)

Inspection Process

-

Rule-based pre-processing

Pre-processing of captured images

for defect inspection -

MOAI inspection process

Deep learning neural network learning

and optimized inspection model creation -

Rule-based post-processing

Post-processing of inspection results

for changing defect criteria and adjusting yield

Introduction Effects

- Replacement of all vision inspections : In addition to dimensional measurement and alignment, deep learning-based atypical defect inspection is performed more efficiently.

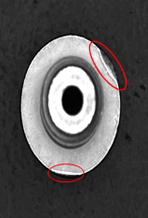

- Large-capacity image inspection : To measure fine defects, images taken at high resolution are divided into a certain size for learning and inspection and are inspected in parallel.

- Product yield control : Using inspection result data, it is possible to change defect standards and adjust product yield by setting the shape and size of defects.

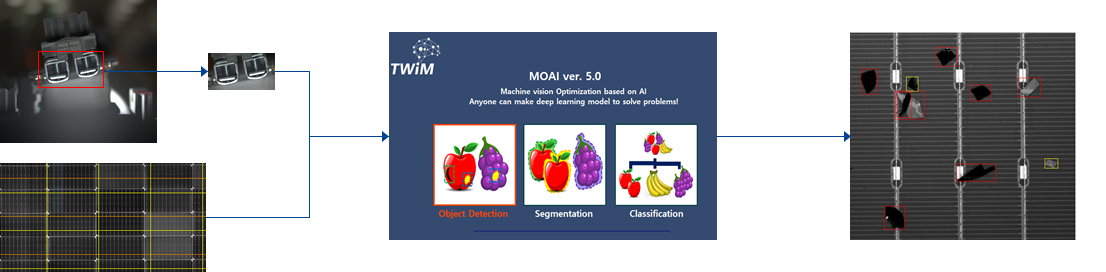

Application Examples and application Fields

- Applicable to automobiles, semiconductors, secondary batteries, solar cells, hydrogen fuel cells, food, pharmaceuticals, metal parts, and all vision inspection fields requiring quality inspection.

Images related to Application Examples

-

Defect inspection in the area of interest

-

Parallel defect inspection

-

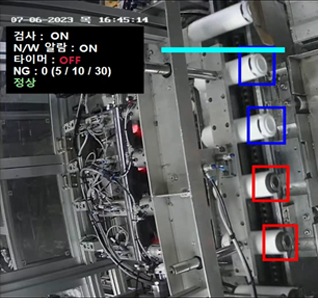

Abnormality detection inside the container

-

Character recognition

-

Steel plate unalloy inspection

-

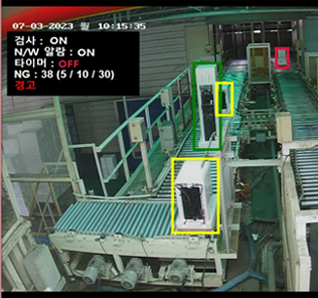

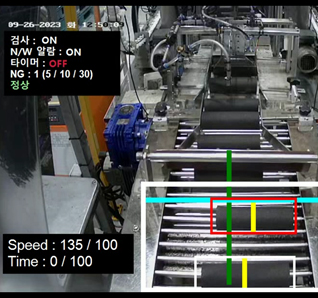

CCTV video analysis (filter cap assembly)

-

CCTV video analysis (product transfer delay)

-

CCTV video analysis (product alignment and facility speed)

Consulting Inquiries

Need more information or consulting? Contact us!

TWIM Sales Team