Business Area

HOME

Business Area

Machine Vision

Machine Vision Solution

Machine Vision Solution

Machine Vision Solution

A solution that maximizes the performance of rule-based vision to inspect the

measurement, appearance, and alignment of products.

measurement, appearance, and alignment of products.

TWIM machine vision solution, which maximizes the performance of rule-based vision, ensures optimization of product measurement inspection, appearance inspection, and alignment.

Furthermore, we propose system efficiency tailored to your needs through optical design according to the process environment.

Adopt TWIM's machine vision solution, which has already proven its performance in numerous business areas and projects.

Furthermore, we propose system efficiency tailored to your needs through optical design according to the process environment.

Adopt TWIM's machine vision solution, which has already proven its performance in numerous business areas and projects.

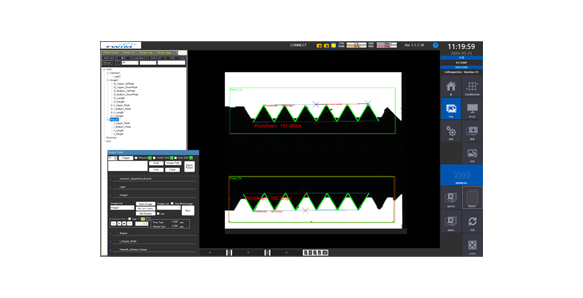

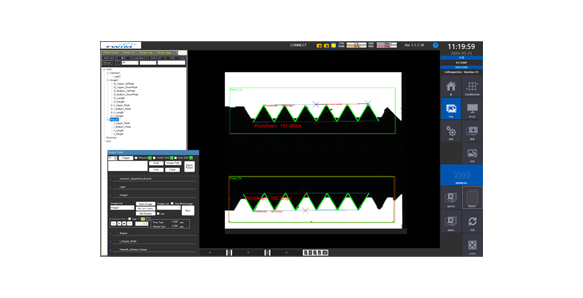

A one-touch machine vision solution capable of performing everything from product measurement to complex appearance inspection, alignment, and data analysis with simple settings. A one-touch machine vision solution capable of performing everything from product measurement to complex appearance inspection, alignment, and data analysis with simple settings. T-AIS(Vision Inspection Platform)

Overview

Software that allows users to perform desired measurements, appearance inspections (Rule, AI), and alignment without the need for developers, and to process, store, and analyze the desired data.

Features (Differentiation)

- Users can flexibly perform desired product measurements, appearance inspections (Rule, AI), and alignment inspections with their own settings.

- Rule-based and AI inspections can be set and used according to user preferences.

- It has extensibility to use or extract desired data by writing simple scripts.

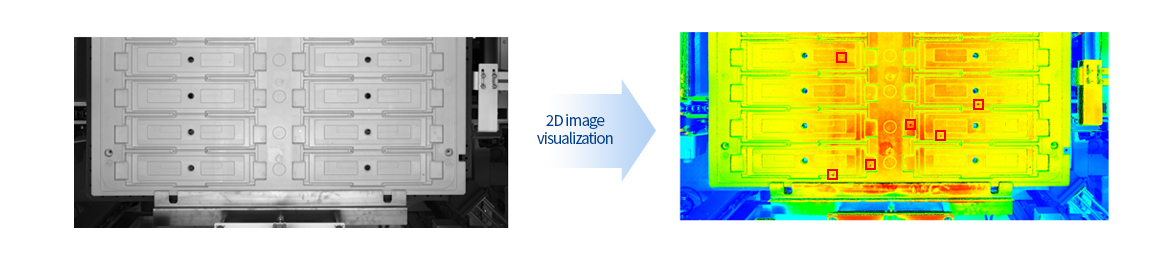

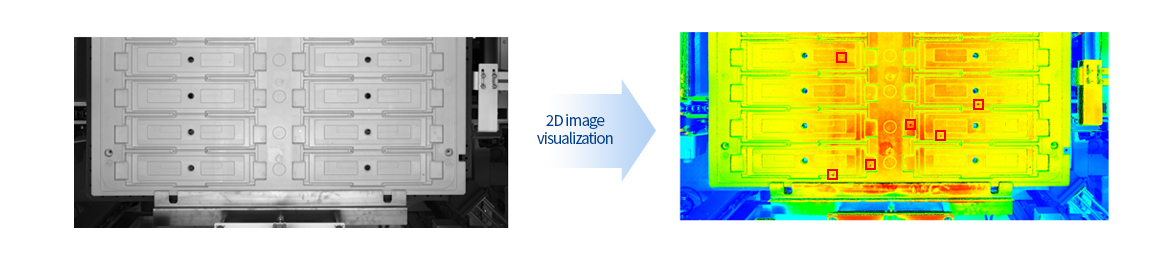

- It has a viewer function that converts 2D images into 3D to visually view the characteristics of the inspection target.

- Users can log desired data by setting, and there is an analysis function to check yield and defect tendencies through the log.

Features

Performs a composite inspection of atypical shapes through rule-based measurement, alignment, and AI inspection by adding desired functions to the settings.

Trend analysis function by yield and defect through analyzer

Converts and provides data from the captured videos to visually show the differences and features.

Introduction Effects

- Ensures flexibility and scalability

- Enhances development productivity

- Reduces setup time and allows quick process application

- Improves reliability and process efficiency

Application Examples

- Company H : Applied the total machine vision solution to the solar module production line

- Company H : Applied the total machine vision solution to the solar inverter production line

- Company S : Applied to the secondary battery module and battery production line

- Company H : Applied the machine vision inspection to new fuel cell materials

Application Field

- Applicable to all existing machine vision solution applications

Consulting Inquiries

Need more information or consulting? Contact us!

TWIM Sales Team