However, it is not possible to introduce unproven AI testing software in the field.

With MOAI, TWIM's AI inspection software with successful deployment experience in a wide range of industries, product defects can be accurately and quickly inspected to dramatically reduce defect rates. Also, TWIM's MOAI customize for each process, so the process adaptability is the best.

Now, with MOAI, increase production quality and increase your brand credibility.

Optimized machine vision with AI MOAI(Machine vision Optimization based on AI)

- Easy and simple learning and inspection environment for first-time users

- Capable of inspecting atypical and minute defects in products or parts

- Optimized deep learning model inference time for rapid inspection

- Defect detection rate over 99%, reducing labor costs and enhancing quality

- Process improvement and production efficiency through big data analysis of inspection results

- Applicable to defect inspection in all manufacturing fields requiring quality inspection

- Can be developed in various forms, such as multi-joint robots or inspection equipment equipped with MOAI

-

Enter sample image

Enter sample imageVaries by product but requires a minimum of 50 images

-

Data labeling

Data labelingLabel by defect part

-

Proceeding with deep learning

Proceeding with deep learningProceed with learning with deep learning algorithms developed by company

-

Model generation

Model generationCreate inspection models optimized for manufacturing sites

-

Enter inspection image

Enter inspection imageenter the image to inspect

-

Output test results

Output test resultsDisplay test results to users

- All visual inspection replaceable :

Any inspection that can be done with the eyes is replaceable, enabling processes that have not been traditional rule-based vision inspection to be automated through deep learning vision inspection - Improve quality and productivity :

Quality and productivity improvement : The quality and productivity of the process depends on the proficiency and condition of the inspector. Human judgment errors are ±3% and defective detection rate is around 97%, but defect detection rate is 99-100% when using deep learning vision inspection - Reduce costs :

Machines can operate 24 hours a day without being affected by labor issues such as the 52-hour work system and the minimum wage. In the case of companies that have introduced deep learning vision inspections, it replaces 24 times of 3 shifts and replaces about 8 workers a day.

- Company L : AI vision inspection for circuit breakers

- Company K : AI vision inspection for stick pouches

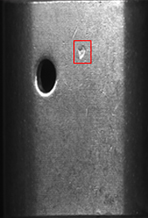

- Company M/Company K/Company S : AI vision inspection for automotive metal parts

- Company H : AI vision inspection for automobile part assembly

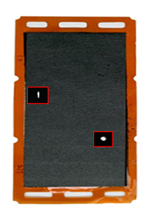

- Company B/Company N : AI vision inspection for diagnostic kits

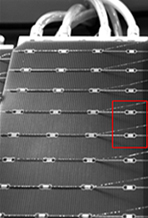

- Company H : AI vision inspection for solar cells

- Company S : AI vision inspection for secondary batteries

- Company C : AI vision inspection for water purifiers, bidets, filters

- Company H : AI video inspection for unalloyed steel plates with CCTV

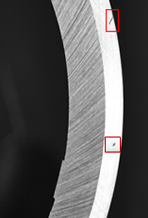

- Company H : AI vision inspection for hydrogen fuel cells

-

Solar cell defect inspection

-

Hydrogen battery defect inspection

-

Secondary battery defect inspection

-

Water purifier defect inspection

-

Parts assembly inspection

-

Metal parts defect inspection (1)

-

Metal parts defect inspection (2)

-

Diagnostic kit defect inspection

-

Food container defect inspection

-

Pouch defect inspection

-

Hot melt defect inspection

-

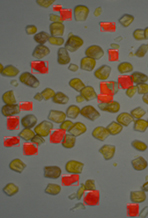

Corn defect inspection

-

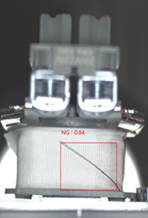

Circuit breaker appearance defect inspection

-

Product information character recognition

- Automobile : Inspection for vehicle exterior, tire dents, cracks, and scratches

- Semiconductor : Wafer defect inspection, wafer defect type classification inspection

- Metal parts : Inspection for external defects such as scratches, dents, dents, burrs, etc.

- Secondary battery : Vision inspection in automotive secondary battery cells/modules/packs process

- Solar cell : Vision inspection in solar cell/module/package process

- Hydrogen fuel cell : Vision inspection of key hydrogen fuel cell components

- Food : Inspection for packaging wrinkles, sealing defects, foreign substances, and container exterior

- Pharmaceutical : Inspection for packaging defects, broken tablets, foreign substances

- Applicable to all vision inspection fields requiring quality inspection