Business Area

HOME

Business Area

Machine Vision

3D Robot Vision

3D Robot Vision

3D Robot Vision

Combining 3D vision and AI to realize robot motion guidance and Pick & Place

Combining 3D vision and AI to realize robot motion guidance and Pick & Place

When workers constantly pick up raw materials and place them on the production line, it not only causes boredom due to simple repetitive tasks, but also causes musculoskeletal damage.

However, in order to use a robot, there was a contradiction in that workers had to arrange the materials well so that the robot could pick them up, right?

By equipping robots with 3D vision for eyes and AI algorithms for intelligence, the robots can autonomously identify materials, determine precise positions and angles, and place them accurately, freeing up workers to focus on more creative and high-value tasks.

Additionally, the robots can perform defect inspections while picking materials.

Now, leave the material loading/unloading work that people do not want to do to TWIM 3D Robot Vision. It performs weekend and night shifts without any complaints.

When workers constantly pick up raw materials and place them on the production line, it not only causes boredom due to simple repetitive tasks, but also causes musculoskeletal damage.

However, in order to use a robot, there was a contradiction in that workers had to arrange the materials well so that the robot could pick them up, right?

By equipping robots with 3D vision for eyes and AI algorithms for intelligence, the robots can autonomously identify materials, determine precise positions and angles, and place them accurately, freeing up workers to focus on more creative and high-value tasks.

Additionally, the robots can perform defect inspections while picking materials.

Now, leave the material loading/unloading work that people do not want to do to TWIM 3D Robot Vision. It performs weekend and night shifts without any complaints.

Combining 3D vision and AI to realize robot motion guidance and Pick & Place 3D Robot Vision

Overview

Current industrial robots move only along predetermined paths. When tasks require visual confirmation of the location or condition of materials, even simple tasks necessitate human intervention for tedious and repetitive work.

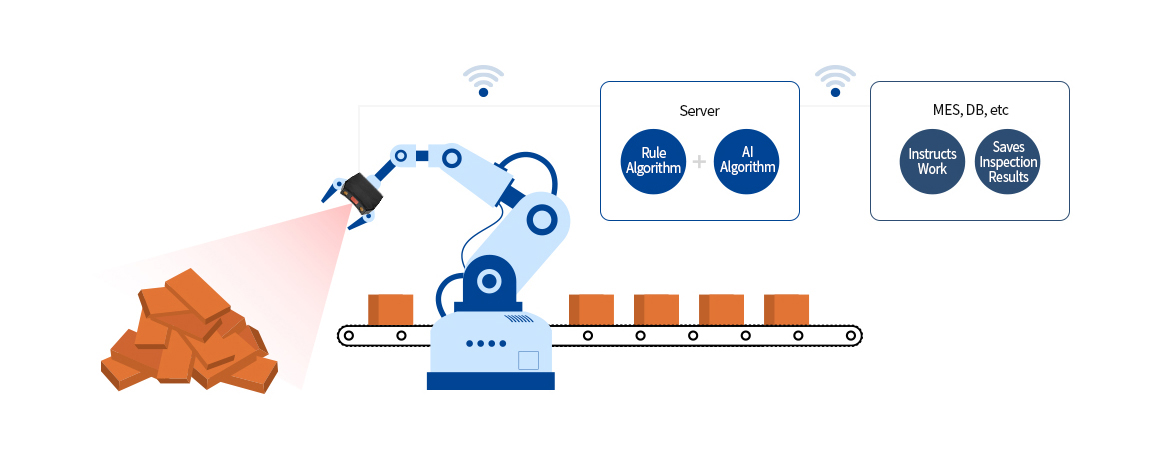

TWIM's 3D Robot Vision team presents the “3D Vision AI Robot Control” solution, integrating AI recognition technology, 3D sensor technology, 3D data processing technology, and robot operation technology to enable robots to see, judge, and move autonomously.

TWIM's 3D Robot Vision team presents the “3D Vision AI Robot Control” solution, integrating AI recognition technology, 3D sensor technology, 3D data processing technology, and robot operation technology to enable robots to see, judge, and move autonomously.

Features

-

Direct Handling of 3D Data + Custom Algorithms

The standard algorithms of existing 3D vision show good performance only for specific material shapes, and often fail to deliver the performance shown in the demo in actual mass production sites with diverse shapes, lighting, and features. The TWIM 3D Robot Vision team handles 3D data at the raw data level and customizes algorithms optimized for the target material, proving more accurate picking points and faster algorithm speeds to customers. -

Coding From Scratch

To meet diverse customer requirements, flexible integration with various types of PLC, MES, and robots is essential. The solution must also accommodate optimized work sequences and scenario-based responses to various exceptions. The TWIM 3D Robot Vision Team provides a solution optimized for customer sites by directly coding all parts, including communication, GUI, 3D graphics, algorithms, AI application modules, and sensor control, from scratch. -

AI and Rule Hybrid Application

By applying both AI recognition algorithms and rule-based recognition algorithms to the 2D and 3D data obtained on-site, higher recognition rates are achieved compared to using AI or rule algorithms alone. This approach ensures optimal recognition and measurement algorithms for the highest positional accuracy. -

Comparative Application in Mass Production Lines

At sites where the performance of the Robot picking system equipped with Japan's famous 3D vision is below expectations, replacing the 3D vision with the TWIM 3D Robot Vision Solution resulted in higher recognition rates, faster operation, more precise picking points, better accommodation of customer requirements, and fewer on-site alarms, thus satisfying customers.

Application Field

-

Pick & Place

This solution detects the exact picking point of randomly located materials and then moves the robot to that point to pick in the material loading process. -

Robot Guidance

In riveting, bolting, and dispensing processes, this solution detects the exact positions and orientations of randomly located materials, guiding the robot to the target points to perform riveting, bolting, dispensing, etc. -

3D Inspection

This solution acquires precise 3D shape values using laser scan sensors and performs inspections and measurements as requested by customers.

Consulting Inquiries

Need more information or consulting? Contact us!

TWIM Sales Team